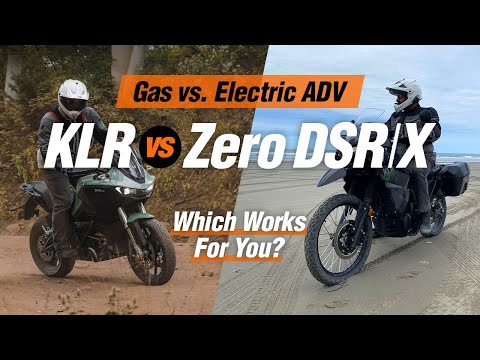

I was riding my trusty DR650ES deep in Oregon’s desolate “Outback” when I smelled gas. I immediately came to a halt on the dusty, bumpy two-track access road that traced along soaring overhead power lines that carried power to the entire West Coast and beyond. Out here, livestock and rattlesnakes outnumber people about 1,000 to one—maybe 10,000 to 1—and help is far, far away. Heck, I hadn’t even seen a cow for miles, and the desert sagebrush stretched off into the distant hills in every direction. Cell phone service? It had tailed off many hours ago. I looked down to see my fuel supply dripping onto my left boot.

I immediately shut off the petcock and the gas left in the transparent fuel line slowly drained away—a good sign, all things considered. Since the DR650 uses a carburetor and not fuel injection, the line was gravity-fed and not pressurized, otherwise it would have been a likely much more flammable spray of gas, not a drip. Clearly, the rupture was small, judging by the slow exit of the gas. And a quick check of the gas tank showed a fair bit of fuel remaining, so it didn’t appear the gas had been leaking for long. I wasn’t stranded… yet, and I had a small bottle of fuel tucked in my panniers for emergencies. But reserve or no, if I didn’t fix the leak, there was no way the DR was going to make it to my far-flung destination without running out of gas—or igniting like a rolling sideshow attraction.

Using pliers, I released the small metal collar on the gas line where it met the carburetor and then eased the fuel line off the carburetor receiver. Another bit of luck: However it had happened, the rupture was right at the point of contact with the carburetor, so if I was careful, I could trim the line back just a few millimeters and still re-attach it with the small amount of slack remaining, a good thing as I did not pack any extra fuel line with me (promptly noted for future rides).

With a small, razor-sharp knife, I carefully and cleanly cut the thick gas line just above the rupture, then eased the line back onto the carburetor connection post and slid the metal line cinch back into place with pliers. I turned the gas tank petcock back on and fuel promptly flowed back down the line to the carburetor. I waited for the drip drip drip of the gas to resume, but none came. So far, so good.

Possible stranding, inferno, injury and disaster averted (for now, at least), I rechecked my gear, tightened a problematic small screw that held a panel in place, adjusted a throttle cable that had become a bit too slack and had a quick drink of water from my hydration pack while rechecking the line for signs of leakage. None appeared. The reliable Suzuki started right back up and off I went down the trail, a plume of dust blowing slowly across the sagebrush that carpeted this section of Oregon’s sun-baked high desert region. I glanced down often at the fuel line as I rode, but no new signs of a leak appeared. Hours later, I arrived safely at my destination, low on gas and my pant leg emitting a faint odor of unleaded, but at least I had a story to tell.

Motorcyclists who leave the pavement behind to go adventure riding must be both highly self-sufficient and space efficient, especially given the typical space restrictions for gear versus a car or truck. In worst-case scenarios, there are technologies that allow for communication even in the most desolate of locations in case of dire emergencies, but for the most part, if you want to get underway again on your own in the short term, you have to bring the needed tools, parts and repair skills with you. To repair my leaky fuel line out in the literal middle of nowhere, where there was no cell service and no nearby… anything, I pulled a single tool from my jacket pocket: A Leatherman Wave Plus.

It’s a tool I’ve been carrying in some form—and pretty much the same form—since I bought my first Leatherman three decades ago. And recently, I thought it was well past time to go see exactly how they are made by visiting Leatherman’s headquarters and manufacturing facility here in my hometown of Portland, Oregon, where the company has been based since its inception in the late 1970s.

A Leatherman By Any Other Name

First off, there’s the unusual name. It doesn’t come from a focus group, branding exercise or the mind of someone who thinks up those clever app and internet company names. It comes from the man who invented the Leatherman multitool, Tim Leatherman. His family emigrated from Europe generations ago and upon entry to the U.S. their name was interpreted by immigration officials as “Leatherman” and since they were making a new start in America, they basically decided to just go with it. After decades growing the company, founder Tim Leatherman turned the company over to his son, Lee Leatherman, who met me at the Leatherman manufacturing plant in Northeast Portland.

The idea for the Leatherman multitool came to Tim in the mid-1970s. While on a low-budget tour through Europe with his beloved partner Chau, they bought a used Fiat that needed consistent tinkering to continue their adventure. Tim rounded up a palette of tools to keep the car running, but one thing he really wanted was a single tool that was more useful than a pocket knife. He couldn’t find it for sale in Europe or when he returned to the the U.S.

Tim Leatherman with the Fiat 600 he and his partner drove (when it ran) during their 1970s tour of Europe. Photo courtesy of Leatherman

Once back home in Oregon, Tim went to work in his garage and cobbled together a menagerie of parts to make a new kind of tool, and he had a clear design vision. The key? The primary tool should be a pair of pliers instead of a knife blade, although that was also included in the folding handles of the tool, among other useful bits. The first prototypes were called “Mr. Crunch,” and that original prototype has essentially the same form factor as the Leatherman Wave Plus I used to repair my Suzuki. It’s a design that has revolutionized the “pocket knife” paradigm if you will, giving us the now ubiquitous “multitool.”

Ultimately, the “Mr. Crunch” name didn’t stick, but Tim got the design patented and after years of refinement (and many rejections from resellers), the first Leatherman multitools, called the Pocket Survival Tool (or PST) came on the market, with Cabela’s placing the first mass production order. I bought my first Leatherman, by then called the Super Tool (below, right), shortly after it debuted a few years later.

A new Leatherman Free P4 (left) and my original Super Tool I received as a gift. Photo: William Roberson

As luck would have it, I received another Super Tool as a birthday gift. I still have that one, largely unused, and it has pride of place in my toolbox, still in its black leather snap belt case with “Leatherman” in gold script. It is a small mechanical treasure. The Super Tool I originally purchased went on many adventures until it went missing, and I replaced it with the Wave Plus, which I still carry pretty much every day and everywhere I go.

Tim’s instincts for the original Mr.Crunch were spot on: Pliers are much more useful and practical than a knife, but it’s still nice to have both. It helped fix my leaky DR—and has also revived more than a few cars and motorcycles, sped up home repairs, helped with bicycle repairs and even handled delicate sliver removal operations. Stories abound from Leatherman users who fixed something that allowed their journey, adventure or even their lives to continue. Like a wallet and our now almost indispensable smartphones, a Leatherman is a standard everyday carry item for myself and for many others, and it has inspired many imitators.

How It’s Made, And Where It’s Made

Entrance to the Leatherman factory and offices in Portland, Oregon. Photo: William Roberson

Lee Leatherman told ADVrider.com that every Leatherman product is made at his Portland plant using U.S.-sourced materials. Nothing is sourced from other countries, including the metals and packaging. Some parts are sent out to other Leatherman facilities around the Portland area for special treatment, but Lee says one of the things he and his family are most proud of is to be able to offer workers living-wage jobs with benefits building a U.S.-made product with a long-standing reputation for quality.

Indeed, Leatherman guarantees their tools for 25 years and will repair them essentially with no questions asked. With a chuckle, I told Lee I thought my original Leatherman Super Tool was out of warranty, but Lee not-jokingly said if it ever broke, to send it in and his staff would try to make it right, no matter when it was made—and that essentially goes for anyone who owns a Leatherman multitool from any year. Just contact them, Lee said. And yes, they keep spare parts on hand at the factory.

A steel blank and a CNC-milled tool handle. Photo: William Roberson

Out on the factory floor, Leatherman employees watch over large hydraulic presses as they stamp out parts from rolls of high-grade steel. The parts are sorted for further finishing and then assembly into the multitools. I was astonished to learn that all Leatherman multi tools are hand-assembled by workers at the Portland plant, not by robots or in facilities overseas.

Plier bits ready to assembled into a finished tool. Photo: William Roberson

Lee said at one time they had actually looked into using robots to assemble the multitools, and small, simple robots, overseen by human workers, are used in some sorting and tool finishing processes for consistency and quality assurance. But Lee says that so far, no automaton they have tried could give the tools the very exact, precise feel and smoothness Leatherman tools have when you open and use them.

A Leatherman employee assembles a set of tools at the end of the production process. Photo: William Roberson

Instead, dozens of people who specialize in making certain kinds of Leatherman products chat away while working in organized stations, or listen to earbuds or just focus on assembling the multitools, then “feel testing” the completed tools before they are sent out for more QC checks and retail packaging, which is often made from recycled materials. The workers do not look rushed or as though they are working in some sweatshop. Indeed, the factory floor vibe is light and friendly, and no one looks to be working under pressure-cooker conditions.

A small robot give a pliers section a polish ahead of integration into a finished tool. Photo : William Roberson

In an era of ever-growing robotic sophistication often used to build highly complex machines like cars and consumer electronics, the human-staffed Leatherman assembly stations may be a throwback, but they are also technically astute, with workers throughout the factory using numerous computers, measuring devices and other technologies to get the pieces just right. But in the end, it comes down to how the employee assembling the finished product thinks the tool feels, and then makes any final adjustments. Lee says that for the near future, he doubts the company will move to assembly bots, even with an expected increase in production with a large new facility coming online next door. That final level of quality from the assembly staff—and the people that put the tools together—are more valuable, Lee said.

A Long History, And Some New Directions

Decades of refinement later, the Leatherman multitool has featured numerous tool options, but until recently, has typically hewed close to that original recipe: a folding pair of pliers, plus everything else in the handles. It’s a winning formula, and Lee Leatherman says the company has sold over two million units over the years, and employs over 150 people to make them at his Portland facility—with expansion underway in a huge building across the street. I am sure that over the years, Leatherman has been approached by numerous interested parties that have made outsized offers to buy the company, with certain “efficiency” ideas around automation and location in mind, but the company remains privately held and run by the Leatherman family in Portland.

Leatherman has extensive archives for most every tool designed by the company. Photo: William Roberson

Down a long hallway in the office portion of the Leatherman facility, there are framed photos of every major product Leatherman has produced. There’s also an archive of the actual products, and a large flat file of the drafting drawings of the early tools, going back to original designs by Tim Leatherman and his early team (above). Current tools are mainly created using modern computer design stations, but always with an eye towards human construction and operation.

Not-so-secret lair of the Leatherman Garage skunkworks. Photo: William Roberson

However, with Lee taking over as president and owner of Leatherman, some changes are afoot. Lee assembled a small think tank of designers and formed a unit called the Leatherman Garage, an homage to his father who designed the original Mr. Crunch in the family garage. The team works in a small room on the second floor of the building with the division name written on a Post-It note on the door.

The “new” Mr. Crunch came in a leather case like many of the original tools. Photo: Leatherman

In 2022, the Garage team produced their first product, a tribute to Tim’s first multitool. The name? Mr. Crunch, of course (above). It was limited to just 500 units and sold for $200, instead of some ridiculous “limited edition” price tag. I actually tried to buy one without success: they literally sold out online in seconds. If you want one, you can find them on eBay for four figures. But I did get to see and handle a Mr. Crunch, shown below by Lee with an image of the original Mr. Crunch prototype behind him.

Lee Leatherman with a new Mr. Crunch and the original in background. Photo: William Roberson

One key feature of the original Mr. Crunch prototype was an interior set of secondary cutting blades that slid into place inside the pliers when the tool was opened. Back in the 1970s, it was too much of an engineering challenge to mass produce, and did not appear in the early tools. But modern design and manufacturing methods allowed it to be integrated into the new Mr. Crunch, and to watch the parts smoothly move within the tool as it unfolds gives a clue as to the original design ambitions Tim Leatherman was pursuing even back in the drafting table days of the 1970s. While CAD-CAM design and modern production tools now make it possible, Lee said he and his team still had to personally hand-finish many of the Mr. Crunch units to assure top quality.

Since the Mr. Crunch debuted, the Garage team has issued three more special editions in larger numbers that sold out just the same. The second tool was called the Darkside, a 21-tool version of an existing design but with a black finish and teal borders on the handle rails. It also includes what may be a first for a multitool: a small pen for writing, which removes from the tool for use.

The Leatherman Darkside features a black finish and teal blue highlights. Photo: Leatherman

There are also scissors, three types of sharp cutting blades, and much more. Lee said that although the Darkside was based on existing designs, it was re-thought to incorporate new tools and ideas, and also to try out new manufacturing processes around colors and materials.

For the third Garage issue, called Parts, Lee and his team went in an unexpected direction. Instead of adding complexity and tools to the plier-based design, they made what appears to be a simple folding knife. It’s called “Parts” because it’s made from pre-existing parts they found at the factory, and it features two interchangeable blades and a tool to swap them out.

Leatherman Parts by the Garage team. Photo: Leatherman

One blade is a pocketknife-like 3-inch blade while the second is a tougher, reshaped “work knife” suitable for slicing open boxes, cutting through packing bands and so forth. Lee says it makes a good companion tool for users that consistently need a larger, more robust blade than the slim but razor-sharp smaller blades tucked into the handle of the regular multitools. It also features splashes of light-colored material on the handle and teal points on the spine and opening button. For those scratching their heads over why Leatherman would produce such a product, Lee said the Garage issues also act as test cases for features that may appear in new models that will see much larger production runs.

The EUROPE75 tool with all-important corkscrew. Photo: Leatherman

A fourth Garage model, called EUROPE75, is also based on a more traditional folding-knife design but it includes a sentimental nod to his parents by including an all-important-while-traveling-in-Europe tool: a corkscrew. A bottle opener is also included, along with some other bits that may help keep an old Fiat (or your bike) running. But at least that bottle of vino is covered.

Leatherman has the pliers-based multitool market well covered with their popular Wave, Surge, and Charge lines, so Lee says the company is expanding their offerings with features seen on some of the Garage small-batch tools in new products such as the Free line of multi-tools and folding knives (with tools) that feature magnetic closure for one-handed operation, and even a popular medical-grade pair of field-operation folding scissors called Raptor Rescue. There’s also a new “Crunch” model that features vise-grip type functionality. Additionally, new colors are on offer for some models, and many of the tools can now be customized while ordering with specific tools, colors, finishes and other personalization.

But for many, the original Leatherman design is still the most useful, and most iconic. I still carry my Wave Plus pretty much everywhere, and even paid to ship it back home from an airport after carrying it out of habit, nearly missing my flight. For myself and many adventure seekers, the small lump of metal clipped to our belt or tucked away in our gear gives some peace of mind that whatever happens, it’s likely a problem that can be fixed, given the right tool, so our journeys can continue.

Special thanks to Lee Leatherman and his staff for taking the time to show ADVrider.com around the Portland facility. Bill has more details and photos from his visit here.