A new riding season is fast approaching in the northern hemisphere.

Did you get a new bike? Did you upgrade your old ride? Are you revising your tool kit?

I bump into riders along the trail and when they bring out their tools some of them look like they have enough with them to open up a motorcycle shop . . . I say this from experience because I owned a motorcycle shop.

So let’s lighten that tool roll and make the ride easier for everyone involved.

There are a few ways to do this, but not all of them do it right. Here are two that succeed.

- The bucket system – put a tool on every visible fastener, throw those that fit into a bucket, and go around your bike top to bottom, side to side. Then dump everything out, eliminate duplicates, and consider what’s left, and look for ways to make the resulting package smaller and lighter.

The bucket system is good, but there might be a better option, and it involves your motorcycle manual and some careful thought.

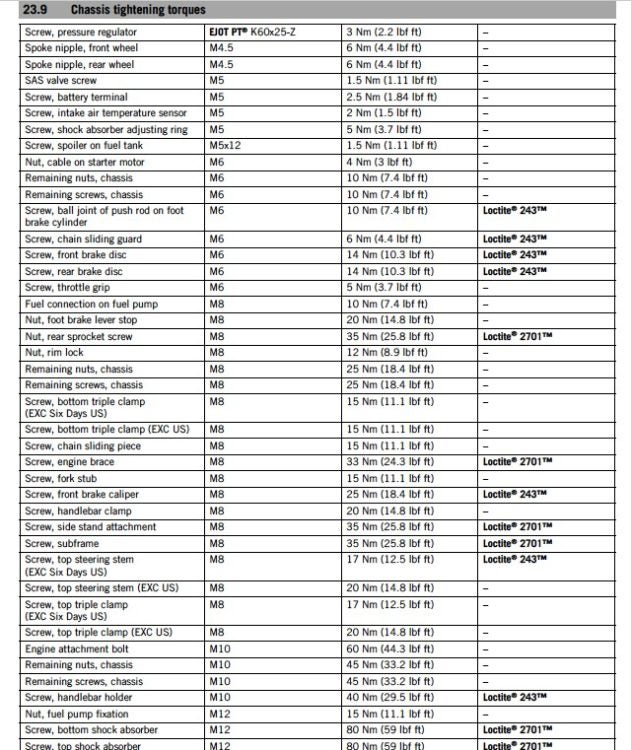

- Get out your service manual and flip to the Specifications page. You should find some torque values like these shown below from the manual for my 2016 KTM 500 EXC.

image – rtwPaul

Many fasteners on that list require a torque value of 25 ft-lb of less, and for these, you can get by with a 1/4 inch drive. You can reduce your toolkit weight by using that smaller drive and taking bigger and heavier tools only for specific needs. Be mindful that you’re unlikely to do any maintenance on the side of the trail that requires getting at internal fasteners, so don’t take tools that you won’t use.

That’s how cottage industry designers might look at their next greatest toolkit idea.

A few of these have landed in front of me for testing. Some were pretty good and some, read on, were not so good.

From the factory

Stock tool kits: KTM vs Honda

Stock tool kits are not all built the same. The KTM version is superior by the look of comparison photos. KTM believes in their owners’ capabilities on the trail and gives them an honest chance of fixing or tightening fasteners. In fact, you could probably take a KTM motorcycle a long way apart with their kit, and not much needs to be added to make it complete and highly functional.

However, the KTM toolkit has a very specific hex drive rather than the normal 1/4″ square drive, and if you lose a socket the chances of replacing it are slim, unless you happen to break down outside a KTM dealership. The same can be said for adding extra bits – it’s a problem. The tool quality, though, is very good, and light in weight.

Photo: rtwpaul

The Honda toolkit just says (to me), “Bring your bike to the dealership; we don’t trust you with real tools!”

Photo: rtwpaul

Which motorcycle company has the WORST toolkit?

Following on from Honda a few companies out there produce low-end tools. You might get by on them in specific circumstances, but the quality and lifespan of their goods might be a little suspect.

The Losers

This little beauty might be good to fix the odd thing on that $20 BMX bike you got for your kid at the thrift store. But its quality and strength are seriously lacking. If you can find one, try to lose it again. Thankfully discontinued.

Photo: rtwpaul

Stockton made a very basic lower-end starter kit, and if you added a few extra bits along with a female 1/4″ drive holder and maybe a multi-tool, you’d be looking at a reasonably complete lightweight kit that you could complete basic jobs with. But if that 1/4″ drive failed, you would have an ugly paperweight. And who uses paper anymore? Currently discontinued, but Stockton’s website is worth a look.

Photo: rtwpaul

A designer had a good idea here, right up to the point of manufacture: a ratchet full of sockets, just one thing to carry. But it was heavy as originally designed, so it was made of composite material. Failure was only a few uses away, but to credit where it’s due, the quality of the sockets was quite good for the price. $10! And, of course, currently discontinued.

Photo: rtwpaul

Photo: rtwpaul

If you are a single-track rider on a skinny bike, who heads out there with absolute minimums, using moose inserts so flats aren’t a concern, and someone who doesn’t like to carry anything on your person, a company called Rock Ready developed a toolkit that was mounted as a handlebar pad. Rock Ready is no longer Ready, but I have seen these pop up on the ADVrider FleaMarket occasionally.

The concept was sound but the potential market share for the company to stay afloat and keep producing was questionable, then poor marketing reduced their chances of success and the company disappeared. Their tool quality was good for the $65 price tag.

Photo: rtwpaul

Black and Decker Ready Wrench – it fits metric and standard nuts and bolts, with the same attachment? Don’t laugh too hard. B&D still makes and sells it and for only $80 you can have one, if you can find it. Here’s a review from an Amazon buyer:

since it’s supposed to fit both sizes it doesn’t fit either size well enough to use. I returned the product and emailed black and decker with my displeasure about the product.

Photo: rtwpaul

Photo: rtwpaul

A guy at another swapmeet handed me this and said, “Pay me next week what you think this is worth, when you realize this is the best-designed set of wrenches ever made! If you’re not 100 percent satisfied toss them away or give them to a friend to use.”

The material is laser cut and about thickness of a coin. I forgot I even had them until five minutes ago; they impressed me that much!

image – rtwPaul

And so we come to the Adjustable Wrench. If you don’t own any tools at all, for anything, a crescent wrench, a hammer, a screwdriver, and a tape measure might be your first purchases for home repair.

For motorcycle repair an adjustable wrench isn’t always great; the head is often too big, and there is potentially slack in the head because of loose threads.

If you are an advocate of the adjustable wrench and have yet to test or use a Knipex equivalent, it’d be interesting to know what you think, and which you’d choose to use on your $20,000 motorcycle after comparing.

Photo: rtwpaul

Photo: rtwpaul

Share in the comments some of the crazy tool failures you’ve had pass through your hands over the years. Photos are a bonus if you have them.